Call us08045479673

60 TPH Mash Plant 20 TPH Pellet Plant

8000.00 INR/Piece

Product Details:

X

60 TPH Mash Plant 20 TPH Pellet Plant Price And Quantity

- 1 Piece

- 8000.00 INR/Piece

- Integrated Option

- Customized as per plant layout

- Fully Automatic

- <85 dB

- 2 mm to 8 mm (adjustable)

- 20 TPH

- 60 TPH

- Electric

- Counterflow Cooler

- Continuous

- Cyclone or Bag Filter

- High Efficiency Steam Conditioner

- Mash and Pellet Feed

- Automatic Centralized System

- Animal Feed Production

- 415 V

- Three Phase

- 50 Hz

- HMI Touch Screen

- Maize, Soybean, Rice Bran, Mash, Pellet, etc.

- High Output For Pellet Size Adjustment

- PLC Based Automated Control System

- Interlocks and Overload Protection

- Mild Steel / SS Components as Required

- Automatic

60 TPH Mash Plant 20 TPH Pellet Plant Trade Information

- 1000 Piece Per Month

- 20-30 Days

- ISO 9001 ; 2008

Product Description

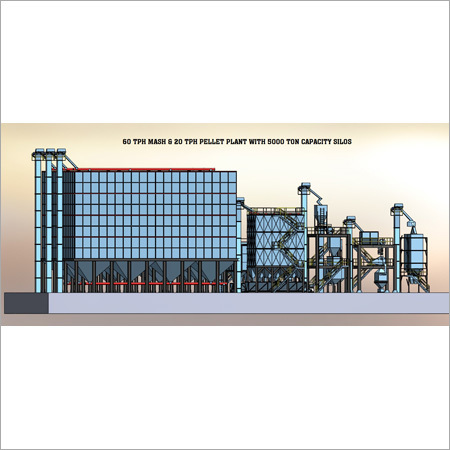

60 TPH Mash Plant & 20 TPH Pellet Plant with 5000 Ton Capacity Silos

Mash and pellet are two renewable and eco-friendly resources that need precise consideration for making. To make the production easy, we have combined two hi-tech operations to deliver 60 TPH Mash Plant 20 TPH Pellet Plant. This system has multiple components that consume less electricity and provide unmeasurable productivity. The offered 60 TPH Mash Plant 20 TPH Pellet Plant is composed of strong metal that keep it resistant against climatic changes.

Advanced Automation for Improved Efficiency

Our feed plant integrates a state-of-the-art PLC-based automated control system, streamlining processes from material intake to finished product. The HMI touch screen simplifies operation, monitoring, and adjustments, ensuring precise control and reducing downtime. Automated greasing and safety interlocks further enhance operational reliability and worker safety.

Flexible Design for Varied Feed Production

With adjustable pellet diameters (2 mm to 8 mm) and the ability to manufacture both mash and pellet feeds, this plant accommodates a diverse range of raw materials such as maize, soybean, rice bran, and more. Customizable installation ensures suitability for any plant layout, supporting varied production requirements and operational needs.

Robust Construction and Clean Operation

The plant uses mild steel construction with stainless steel components as needed, assuring longevity and resistance to corrosion. Effective dust collection systems (cyclone or bag filter) maintain a clean workplace, while the counterflow cooling system and integrated molasses addition option further optimize feed quality and process hygiene.

FAQs of 60 TPH Mash Plant 20 TPH Pellet Plant:

Q: How does the PLC-based automated control system benefit production?

A: The PLC-based automated control system streamlines plant operations by automating critical steps, reducing manual intervention, and enhancing process consistency. It allows real-time monitoring and adjustment through a user-friendly HMI touch screen, ensuring efficient and reliable feed production with reduced risk of human error.Q: What types of raw materials are suitable for this mash and pellet plant?

A: This plant is designed to handle a wide variety of raw materials, including maize, soybean, rice bran, mash, and pellet feed. Its robust design and adaptable processing modules support diverse input types to meet the varied nutritional requirements of animal feed.Q: When is dust collection necessary in the production process?

A: Dust collection is vital during the material handling and pelletizing stages to maintain air quality and a safe working environment. The plant offers either a cyclone or bag filter system, which effectively manages particulate emission throughout continuous operation, keeping the facility clean and compliant with safety standards.Q: Where can the plant be installed, and how is the installation area determined?

A: Installation is tailored to each facilitys unique layout and operational needs. The plants area requirements are customized based on the customers site dimensions and workflow designs, ensuring optimal space utilization and seamless integration into existing operations.Q: What is the process for adjusting pellet diameter?

A: Pellet diameter is easily adjusted between 2 mm and 8 mm through the plants control interface. The system allows operators to select the desired size according to feed type or animal nutrition requirements, facilitating a rapid response to changing production demands.Q: How does the high-efficiency steam conditioner improve feed quality?

A: The steam conditioner optimizes moisture and temperature during feed preparation, enhancing pellet durability and nutritional value. This process not only aids in pathogen reduction but also ensures uniform product quality, making the feed more palatable and digestible for animals.Q: What are the key benefits of using an automatic centralized lubrication system?

A: The automatic centralized lubrication system minimizes maintenance, ensuring continuous operation and reducing downtime. It delivers consistent grease or oil to all critical components, prolonging equipment life and maintaining performance, thereby increasing plant reliability and decreasing operational costs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese