Call us08045479673

5 - 7 TPH Pellet Plant

8000.00 INR/Piece

Product Details:

X

5 - 7 TPH Pellet Plant Price And Quantity

- 8000.00 INR/Piece

- 1 Piece

- 7 Tons per Hour

- 800-1000 hours (depending on raw material)

- 10% - 15%

- Semi-automatic / Fully automatic

- 200 - 300 HP (Depending on configuration)

- Ring Die

- Pelletizing biomass materials such as wood, sawdust, straw, rice husk, agro waste

- 6-12 mm (adjustable)

- 5 - 7 TPH Pellet Plant

- PLC based (optional)

- 60°C - 80°C

- Available

- 380-440 V

- Integrated pellet cooler

- 5 to 7 Tons per Hour

- Mild Steel / Stainless Steel (as per requirement)

- <80 dB

5 - 7 TPH Pellet Plant Trade Information

- 1000 Piece Per Month

- 20-30 Days

- ISO 9001 : 2008

Product Description

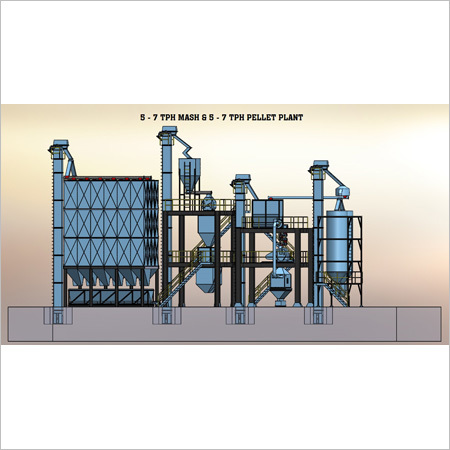

To make a pellet by hand is an easy task. However, to make millions of pellets by hand within short period is relatively impossible. Therefore, we deliver 5-7 TPH Pellet Plant that is basically a heavy-duty and industrial system utilized to make smaller and bigger pellets of different grades. This plant is integrated and configured with high-tech loading, heating, cutting and blending components that work in synchronization to deliver unmatched productivity.

Versatile Pelletizing Capabilities

Designed for a wide range of biomass feedstocks, including wood, sawdust, straw, rice husk, and agro wastes, the 5 - 7 TPH Pellet Plant streamlines the conversion of raw materials into high-quality pellets. Adjustable die settings allow for pellet sizes between 6 and 12 mm, making the plant adaptable to various application needs within the agriculture, energy, and industrial sectors.

Efficient Operation and Longevity

With an integrated cooling system and PLC-based controls (optional), this pellet plant delivers consistent output while minimizing maintenance. The ring die is built for durability, providing a service life of 800 to 1,000 hours depending on feedstock conditions. Built from robust mild steel or stainless steel, the structure ensures longevity even under demanding conditions.

Flexible Automation and Service Support

Catering to different operational preferences, the plant is available in semi-automatic or fully automatic versions. Reliable after-sales service from a reputable exporter, manufacturer, and supplier in India ensures prompt support and expert guidance for installation, maintenance, and troubleshooting, maximizing plant uptime and user satisfaction.

FAQs of 5 - 7 TPH Pellet Plant:

Q: How does the 5 - 7 TPH Pellet Plant operate and what types of feedstock can it process?

A: The pellet plant operates by compressing biomass materials like wood, sawdust, straw, rice husk, and agro waste into dense pellets. It uses a durable ring die and operates within a controlled temperature range to maximize efficiency and output.Q: What are the benefits of the integrated pellet cooler within the system?

A: The integrated pellet cooler rapidly reduces the temperature of freshly formed pellets, ensuring optimal hardness and reducing breakage. This improves pellet quality and supports efficient packaging and storage.Q: When does the ring die require replacement, and how does the type of raw material affect its lifespan?

A: The ring die generally serves between 800 and 1,000 hours, but its actual lifespan varies depending on the abrasiveness of the raw materials. Softer materials tend to extend die life, while harder or more abrasive feedstock might reduce it.Q: Where can this pellet plant be installed and what are the power and voltage requirements?

A: The 5 - 7 TPH Pellet Plant is suitable for installation in industrial sites or large-scale biomass processing facilities. It operates on a voltage range of 380-440 V and requires between 200 and 300 HP of power, depending on configuration.Q: What is the process for adjusting the pellet size, and why is this feature important?

A: Pellet size can be adjusted from 6 to 12 mm by altering die settings. This flexibility allows production of pellets that best suit specific end-use requirements, whether for fuel, feeding, or other applications.Q: How does automation enhance plant operation, and what control options are available?

A: The plant supports both semi-automatic and fully automatic operation modes. Using a PLC-based control system (optional) allows for precise monitoring, adjustment, and consistent pellet production with minimal manual intervention.Q: What after-sales services are provided for this pellet plant?

A: Comprehensive after-sales services include installation assistance, maintenance support, troubleshooting, and supply of spare parts, ensuring smooth and sustained operation of the plant.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese