Call us08045479673

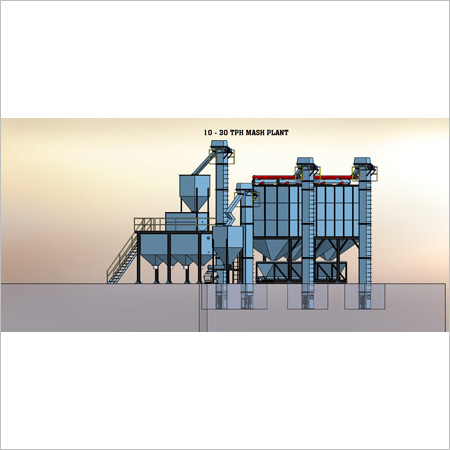

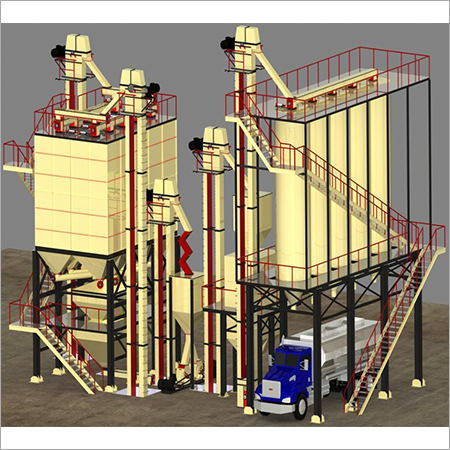

25 Tons\hr-30 Tons\hr Fully Automated Feed Mill Plant

8000.00 - 10000.00 INR/Piece

Product Details:

X

25 Tons\hr-30 Tons\hr Fully Automated Feed Mill Plant Price And Quantity

- 8000.00 - 10000.00 INR/Piece

- 1 , , Piece

25 Tons\hr-30 Tons\hr Fully Automated Feed Mill Plant Trade Information

- 1000 , , Piece Per Month

- 20-30 Days

Product Description

Type:FULLY AUTOMATED FEED MILL PLANT.

Capacity : 25 Tons/hr to 30 Tons/hr

Plant Space requirements : Space of 80 x 32 ft

Key features : SCADA (Supervisory Control and Data Acquisition System) based control system with ease of troubleshooting.

Key Sub elements : Loading screw, Silo Loading Elevator, Screw Conveyor, Raw Material Silo, Weighing Scale, Weighing Scale Hopper, Grinder Loading Screw Conveyor, Grinder Loading Elevator, Magnet chute, Storage Tank, Grinder, Mixer Loading Elevator, Mixer Storage Tank, Mixer, Mixer Hopper, Lorry Silo Elevator, Lorry Silo

- Energy requirements : 220 HP

- Material : MS

- Application : Poultry and cattle feed farms

- Reman Order reference : RI 25TPH to 30TPH

Advanced PLC-Based Automation

This feed mill plant utilizes a PLC-based control system to enable precise, error-free operation and monitoring. The automatic system streamlines all major processing steps, ensuring consistent quality and minimal manual intervention for safety and productivity.

Continuous High-Capacity Output

Designed to support 25 to 30 tons per hour, the plant delivers reliable, uninterrupted production suitable for large-scale livestock, poultry, and cattle feed operations. Its continuous operation mode maximizes throughput and production efficiency.

Comprehensive Safety & Dust Protection

Built with operator safety in mind, the plant features emergency stop and overload protection systems. The integrated cyclone and bag filter dust control mechanisms help maintain a clean working environment and comply with regulatory standards.

Integrated Bagging & Versatile Feed Forms

With an automated packaging system, the plant streamlines feed bagging for efficient storage and dispatch. It can process and package mash, pellet, and crumble forms, offering flexibility to meet market demands.

FAQs of 25 Tons\hr-30 Tons\hr Fully Automated Feed Mill Plant:

Q: How does the plants PLC-based automation improve feed production efficiency?

A: The PLC-based control system automates and coordinates every stage of processinggrinding, mixing, pelletizing, and beyondensuring consistent output, reducing human error, and making real-time adjustments for optimized production.Q: What types of feed can be produced with this automated mill plant?

A: This plant supports the production of mash, pellet, and crumble feed, making it highly versatile for poultry, cattle, and general livestock applications. Each type can be processed and bagged efficiently within the same system.Q: When should you consider installing a 2530 Tons/hr feed mill plant?

A: This plant is ideal for commercial feed producers needing a high-capacity, continuous operationparticularly where consistent supply and automated output up to 30 tons per hour are required.Q: Where can installation and support for the plant be obtained?

A: As an exporter, manufacturer, and supplier in India, installation services are available nationwide to help clients establish and commission the feed mill plant at their facility.Q: What steps are involved in the feed production process within this plant?

A: The process includes grinding raw materials, mixing for uniformity, pelletizing or crumbling as needed, cooling finished products, screening, and finally, automatic baggingeach step integrated for seamless output.Q: How does the cyclone and bag filter system benefit plant operations?

A: This dust control setup reduces airborne particles during processing, maintaining a cleaner work environment and minimizing health and fire hazards, while helping the plant adhere to environmental safety standards.Q: What are the safety features incorporated in this feed mill plant?

A: Safety is enhanced with features such as an emergency stop function and overload protection, ensuring the equipment and operators are safeguarded during all phases of operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese