Call us08045479673

3 Ton\hr-5Ton\hr Standard Feed mill Plant

8000.00 - 10000.00 INR/Piece

Product Details:

X

3 Ton\hr-5Ton\hr Standard Feed mill Plant Price And Quantity

- 1 , , Piece

- 8000.00 - 10000.00 INR/Piece

3 Ton\hr-5Ton\hr Standard Feed mill Plant Trade Information

- 1000 , , Piece Per Month

- 20-30 Days

Product Description

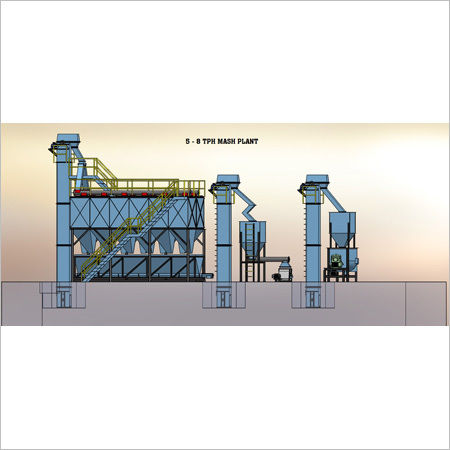

Type : Feed mill Plant.

Capacity : 3 Tons/hr to 5 Tons/hr

Plant Space requirements : Space of 25 x 15 ft

Key features : Centralized control system with ease of troubleshooting

Key Sub elements : Screw Conveyor, Magnet chute, Grinder, Elevator, Storage Tank, Mixer Elevator, Mixer Storage Tank & Mixer

- Energy requirements : 31 to 41 HP

- Material : MS

- Color : As per Customer Requirement

- Application : Poultry and cattle feed farms

- Reman Order reference : REW18002 3TPH to 5TPH

Flexible Feed Types and Processing

Catering to modern agricultural needs, the plant produces pellets, crumbles, and mash, allowing farmers and commercial enterprises to diversify their feed offerings. With provisions for both continuous and batch processing, it adapts easily to fluctuating demand, helping maximize output while maintaining consistent quality across all feed types.

Customizable Design for Varied Requirements

Designed with customization in mind, this feed mill plant can be tailored to fit unique spatial and production demands. From choosing the right capacity and automation grade to adapting dimensional specifications, users can configure the system to achieve optimal workflow and efficiency in their particular setting.

Comprehensive Support and Compliance

Our service extends beyond installation, providing clients with ongoing technical support and readily available spare parts. With a strong focus on safety and environmental standards, every plant is engineered to meet stringent industrial norms, ensuring operational reliability and regulatory peace of mind for your feed business.

FAQs of 3 Ton\hr-5Ton\hr Standard Feed mill Plant:

Q: How is the 3 Ton/hr5 Ton/hr feed mill plant installed and commissioned?

A: On-site installation and commissioning are provided by experienced technicians to ensure the plant is properly set up, tested, and ready for efficient production. The customizable dimensions allow easy integration into your available space.Q: What animal feed types can be produced with this plant?

A: This plant can manufacture pellets, crumbles, and mash, giving operators flexibility to meet various nutritional needs and preferences in the animal feed industry.Q: When should the PLC-based control system be considered?

A: A PLC-based control system is recommended for operations seeking enhanced automation, improved process monitoring, and efficient control over production variables. Its available as an optional upgrade.Q: Where is post-installation support available?

A: We offer comprehensive service support and spare parts supply after installation, ensuring smooth operation and minimal downtime wherever your facility is located.Q: What is the process flow of the feed mill plant?

A: Raw materials are processed through a series of grinding, mixing, pelletizing (or crumbling/mashing), and packaging stages. The system supports both continuous and batch operations for versatile production management.Q: How does this feed mill benefit my operation?

A: With efficient production capacities, customizable design, automated control options, and robust after-sales support, this plant enables scalable, reliable, and cost-effective animal feed manufacturing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese