Call us08045479673

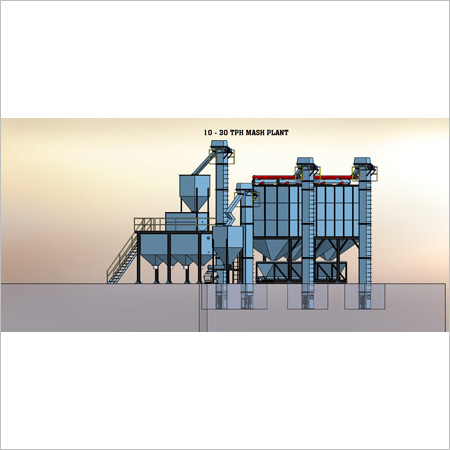

25 Tons\hr-30Tons\hr Standard Feed mill Plant

8000.00 - 10000.00 INR/Piece

Product Details:

X

25 Tons\hr-30Tons\hr Standard Feed mill Plant Price And Quantity

- 1 , , Piece

- 8000.00 - 10000.00 INR/Piece

- Available globally

- Provided by Manufacturer

- Complete feed mill solution for commercial feed manufacturing

- Poultry, Cattle, Fish, Shrimp, Pig Feed

- 380-440 V

- <85 dB

- Automatic

- PLC Controlled with touch screen interface

- 30 Tons per hour

- Grinding, Mixing, Pelletizing, Cooling, Screening, Packing

- Animal feed production

- Mild Steel

- Three Phase

- 50/60 Hz

- 25 Tons/hr - 30 Tons/hr

- Customized as per site requirement

- Varies as per output, typically 200-300 kW

25 Tons\hr-30Tons\hr Standard Feed mill Plant Trade Information

- 1000 , , Piece Per Month

- 20-30 Days

Product Description

Type : Feed mill Plant with Auto Batching

Capacity : 25 Tons/hr to 30 Tons/hr

Plant Space requirements : Space of 75 x 35 Sq.ft

Key features : Centralized control system with ease of troubleshooting

Key Sub elements : Silo Loading Elevator, Screw Conveyor,

Raw Material Silo, Weighing Scale, Weighing Scale Hopper, Grinder Loading Elevator, Magnet chute, Storage Tank, Grinder Screw Conveyor, Grinder, Mixer Loading Elevator, Mixer Storage Tank, Mixer, Mixer Hopper

- Energy requirements : 185 HP

- Material : MS

- Color : As For Customer Requirement

- Application : Poultry and cattle feed farms

- Reman Order reference : RI19020 25TPH to 30TPH

Advanced Automation for Efficient Feed Production

Featuring a sophisticated PLC-controlled system with a touch screen interface, this feed mill plant enables operators to manage complex processes effortlessly. Automated controls ensure consistent feed quality, streamlined routines, and real-time monitoring, enhancing productivity and reducing operational errors.

Versatile Feed Processing Across Livestock Types

The plant supports the production of high-quality feeds for poultry, cattle, fish, shrimp, and pigs, with processes including grinding, mixing, pelletizing, cooling, screening, and packing. This versatility allows commercial feed manufacturers to cater to diverse market demands using one integrated system.

Complete Installation and Global Support Services

Installation and commissioning are handled by experienced manufacturer teams, ensuring each plant is tailored to your site requirements. Comprehensive after-sales support is available worldwide, guaranteeing minimal downtime and efficient operation for long-term success.

FAQs of 25 Tons\hr-30Tons\hr Standard Feed mill Plant:

Q: How is the 25-30 Tons/hr Feed Mill Plant controlled and operated?

A: The feed mill plant operates through a PLC-controlled system with a user-friendly touch screen interface. This advanced automation allows for precise management of each processgrinding, mixing, pelletizing, cooling, screening, and packingensuring optimal productivity and consistent feed quality.Q: What types of animal feed can this plant produce?

A: This plant is engineered to produce high-quality feed for a wide range of animals, including poultry, cattle, fish, shrimp, and pigs. The integrated process line accommodates various feed formulations depending on your production requirements.Q: When is installation and commissioning provided?

A: Installation and commissioning of the feed mill plant are provided by the manufacturer upon purchase, ensuring that the plant is properly set up and optimized at your designated site before production begins.Q: Where can the feed mill plant be installed and what are the dimension options?

A: The plants dimensions are customizable to accommodate different site layouts, making it suitable for installation at commercial feed manufacturing facilities worldwide. The manufacturer tailors the setup to fit available space and production needs.Q: What is the typical power consumption and energy requirements for operation?

A: The plant typically consumes between 200-300 kW, depending on operational output, and runs on 380-440 V, three-phase, with a frequency of 50/60 Hz. This enables reliable performance in various industrial power settings.Q: What are the main steps in the feed production process with this plant?

A: The main processes include grinding raw materials, mixing ingredients, pelletizing, cooling the pellets, screening out fine particles, and packing the final feed products. Each step is fully automated for precision and efficiency.Q: What are the benefits of using this automatic feed mill plant for commercial operations?

A: Adopting this plant ensures high output (up to 30 tons/hr), consistent feed quality, reduced labor costs due to automation, low noise emission (<85 dB), and comprehensive after-sales support. It provides a reliable, all-in-one solution for modern feed manufacturing enterprises.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese