Call us08045479673

12 Tons\hr-15 Tons\hr Standard Feed mill Plant

8000.00 - 10000.00 INR/Piece

Product Details:

X

12 Tons\hr-15 Tons\hr Standard Feed mill Plant Price And Quantity

- 8000.00 - 10000.00 INR/Piece

- 1 , , Piece

12 Tons\hr-15 Tons\hr Standard Feed mill Plant Trade Information

- 1000 , , Piece Per Month

- 20-30 Days

Product Description

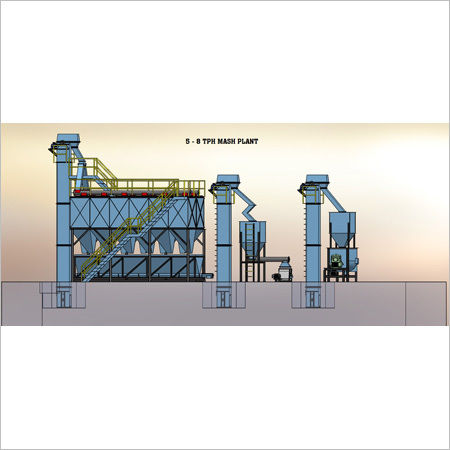

Type : Feed mill Plant with Auto Batching

Capacity : 12 Tons/hr to 15 Tons/hr

Plant Space requirements : Space of 82 x 35 ft

Key features : Centralized control system with ease of troubleshooting

Key Sub elements : Loading screw, Silo Loading Elevator, Screw Conveyor, Raw Material Silo, Weighing Scale, Weighing Scale Hopper, Grinder Loading Elevator, Magnet chute, Storage Tank, Grinder Screw Conveyor, Grinder, Mixer Loading Elevator, Mixer Storage Tank, Mixer, Mixer Hopper, Lorry Silo loading screw, Silo Loading Elevator, Lorry Silo

- Energy requirements : 140 HP

- Material : MS

- Color : As For Customer Requirement

- Application : Poultry and cattle feed farms

- Reman Order reference : REW18020 10TPH to 12TPH

High-Capacity Feed Production

Designed for industrial-scale operations, this feed mill plant guarantees a steady output of up to 15 tons per hour, allowing you to meet substantial production demands without compromising on quality. Its flexible input size range and precise output guarantee consistent feed granulation, maximizing efficiency for manufacturers.

Efficient Installation and Operation

Featuring a fixed installation type, the feed mill plant is built for stability and long-term use. Its standard setup ensures smooth integration into existing infrastructures, minimizing downtime and setup costs. Ideal for manufacturers and suppliers needing robust, high-throughput equipment.

FAQs of 12 Tons\hr-15 Tons\hr Standard Feed mill Plant:

Q: How does the 12-15 Tons/hr feed mill plant work?

A: This feed mill plant processes raw materials with input sizes of up to 30 mm, grinding and mixing them to produce finely granulated feed as small as 5 mm in output. The system operates continuously at a frequency of 50 Hz to deliver a steady production rate of 12 to 15 tons per hour.Q: What materials can be processed in this feed mill plant?

A: The plant is capable of handling a variety of raw materials used in animal feed production, such as grains, cereals, soybeans, and various additives, as long as the input size is up to 30 mm.Q: When should I consider using a fixed-type feed mill plant?

A: A fixed-type feed mill plant is ideal when you require a permanent, high-capacity feed production setup, especially in commercial or industrial contexts where consistent volume and reduced mobility are priorities.Q: Where is the feed mill plant manufactured and exported from?

A: This standard feed mill plant is manufactured and exported by a reputable supplier based in India, serving both domestic and international markets.Q: What is the installation process for the fixed feed mill plant?

A: Professional installation is recommended, involving site preparation, equipment assembly, alignment, and system integration. The manufacturer provides support throughout the process to ensure optimal setup and performance.Q: How can the feed mill plant benefit my production operations?

A: The high output capacity and reliable performance of this plant can significantly enhance production efficiency, reduce operational costs, and ensure consistent feed quality, supporting business growth and competitiveness.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese