Call us08045479673

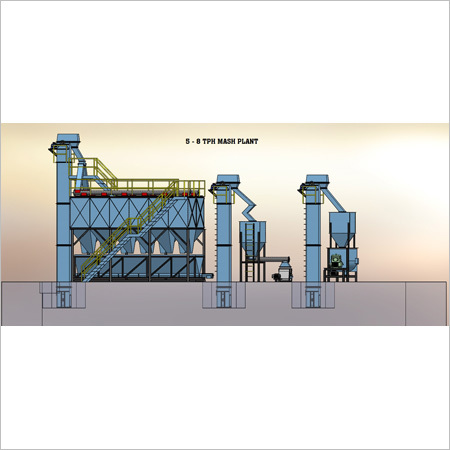

5-8 TPH Mash Plant

8000.00 INR/Piece

Product Details:

X

5-8 TPH Mash Plant Price And Quantity

- 8000.00 INR/Piece

- 1 Piece

5-8 TPH Mash Plant Trade Information

- 1000 Piece Per Month

- 20-30 Days

- ISO 9001 : 2008

Product Description

The offered 5-8 TPH Mash Plant is a heavy-duty system that is integrated with crushing, loading, transferring and many other stations. To stabilize the entire plant, it is required to make huge underground pits to install the vertical pillars. This mainly functions on electricity and in a synchronized manner to provide elevated productivity and speed rate. Our 5-8 TPH Mash Plant is mainly used to make bulk quantity material mash in short period.

High-Efficiency Animal Feed Processing

Our 5-8 TPH Mash Plant streamlines feed production for poultry, cattle, and other livestock. Its continuous operating mode maximizes productivity, while the customizable design ensures seamless integration into existing manufacturing setups. The plants powerful motor and high output per hour make it ideal for commercial feed producers seeking reliable, scalable solutions.

Tailored Plant Design for Your Needs

Every feed mill is unique, which is why our mash plant comes with fully customizable dimensions. We work closely with clients to optimize layouts, ensuring maximum efficiency and space utilization. Whether constructed from mild steel or stainless steel, the plant guarantees longevity and performance to match your specific requirements.

Flexible Automation Options

Choose between semi-automatic and automatic operating modes based on your production demands. Both options offer user-friendly controls and streamlined processes, supporting operators in maintaining high quality and consistent output. Our mash plant can be adapted seamlessly to growing business needs.

FAQs of 5-8 TPH Mash Plant:

Q: How does the 5-8 TPH Mash Plant operate during feed production?

A: The plant operates in a continuous mode, which allows for an uninterrupted feed manufacturing process. This means raw materials are automatically processed, mixed, and output as finished mash feed, enhancing overall efficiency and reducing manual intervention.Q: What materials can be processed using this mash plant?

A: This mash plant is designed for manufacturing poultry, cattle, and other animal feed. It can handle a wide range of feed ingredients, adapting to the specific nutritional requirements of various livestock.Q: When is it advisable to choose an automatic versus a semi-automatic mash plant?

A: An automatic mash plant is best suited for higher-volume production lines where minimal manual supervision is desired, ensuring consistent quality and efficiency. Semi-automatic versions are ideal for smaller operations or those requiring more hands-on process control.Q: Where can this mash plant be installed, and are dimensions flexible?

A: The plant can be installed in feed mills, farms, or commercial processing facilities. Its dimensions are fully customizable, allowing for optimal integration into your available space and existing infrastructure.Q: What is the process involved in producing feed with this plant?

A: Raw materials are first ground and weighed, followed by continuous mixing to achieve a uniform mash. The finished feed is then discharged for packaging, with automation or semi-automation streamlining each step for efficiency and quality.Q: How is the durability of the plant ensured?

A: The plant is constructed from either mild steel or stainless steel, both of which offer excellent longevity and resistance to corrosion. These materials help maintain hygiene and reduce maintenance requirements over time.Q: What are the key benefits of using a 5-8 TPH Mash Plant for feed manufacturing?

A: Key benefits include high throughput (up to 8,000 kg/hour), flexibility in automation, customizable installation, and robust construction suited for demanding production environments. It ultimately contributes to lower production costs and consistent, high-quality animal feed.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese