Call us08045479673

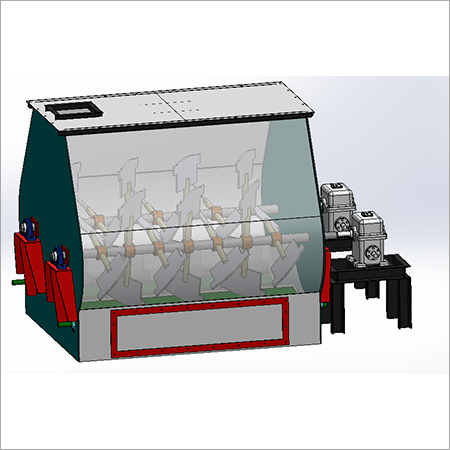

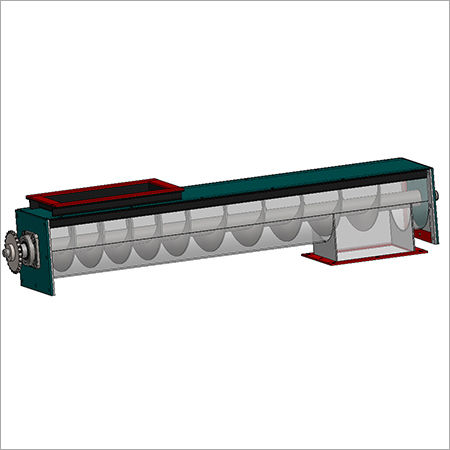

SCREW CONVEYOR

8000.00 - 30000.00 INR/Piece

Product Details:

- Type Screw Conveyor

- Material Mild Steel/ Stainless Steel

- Feature High durability, Corrosion resistant

- Feeding System Manual/Automated

- Size Customized as per requirement

- Color Silver/Grey

- Technology Welding, Fabrication

- Click to view more

X

SCREW CONVEYOR Price And Quantity

- 8000.00 - 30000.00 INR/Piece

- 1 Piece

SCREW CONVEYOR Product Specifications

- Screw Conveyor

- Depends on size and material

- High durability, Corrosion resistant

- Manual/Automated

- Welding, Fabrication

- Silver/Grey

- Mild Steel/ Stainless Steel

- Customized as per requirement

SCREW CONVEYOR Trade Information

- 1000 Piece Per Month

- 20-30 Days

Product Description

The offered Screw Conveyor finds its usage in numerous industries that transfer their semi-solid, paste and liquid material effortlessly to different stations. This is constructed from heavy-duty metal that secure it never reacts with the transferring material throughout its service life. Our Screw Conveyor has an opening through which the material is poured while the nozzle discharges it smoothly.

Versatile Bulk Handling Solution

This screw conveyor adapts seamlessly to various materials and operational requirements, serving a wide range of industries. Whether handling grains in the food sector, chemicals in manufacturing, or raw materials in cement production, it provides secure and efficient transport. The option for manual or automated feeding, along with customizable sizes and finishes, enhances flexibility for specialized applications.

Custom Engineering for Reliable Performance

Engineered using advanced welding and fabrication technologies, each conveyor can be tailored in diameter, length, inclination, and mounting style. With capacities up to 6000 kg/hr and lengths reaching 30 meters, these conveyors accommodate both small and large-scale operations. Varying screw speeds and adjustable angles optimize material movement, while low maintenance and corrosion resistance assure enduring service.

FAQs of SCREW CONVEYOR:

Q: How does the screw conveyor facilitate bulk material handling in different industries?

A: The screw conveyor efficiently transports bulk materials such as grains, chemicals, and cement by moving them through a helical screw mechanism housed within a tubular structure. Its flexible mounting options and customizable design allow it to function reliably in food processing, chemical plants, cement factories, and grain handling facilities, ensuring smooth and consistent material flow.Q: What types of materials can be conveyed using this screw conveyor?

A: This conveyor is ideal for handling a wide variety of bulk materials, including powders, granules, grains, cement, and chemicals. Its construction from mild steel or stainless steel with polished or painted surfaces makes it especially suitable for environments demanding high durability and resistance to corrosion.Q: When should I opt for a horizontal, inclined, or vertical screw conveyor mounting?

A: Horizontal mounting is recommended for standard material transfer over distance, while inclined conveyors are used when elevation of materials is needed, typically up to 45 degrees. Vertical mounting is suitable for lifting materials in restricted spaces or where overhead transfer is required. The choice depends on your facility layout and material movement needs.Q: Where is this screw conveyor most commonly installed?

A: These conveyors are commonly installed in manufacturing units, processing plants, warehouses, grain storage facilities, and bulk material transport terminals. They are especially valuable wherever continuous, reliable, and low-maintenance conveyance of bulk materials is integral to operations.Q: What customization options are available for screw conveyors?

A: Customization includes screw diameter (100 mm to 600 mm), conveyor length (up to 30 meters), material choice (mild steel or stainless steel), surface finish, mounting type (horizontal, inclined, vertical), power source, rotational speed, and feeding system (manual or automated). This ensures the conveyor fits specific application requirements.Q: How does the screw conveyor ensure durability and low maintenance?

A: High durability is achieved through precision welding, strong fabrication, and the use of corrosion-resistant materials like stainless steel. The design minimizes moving parts and uses robust electric motors, contributing to low maintenance needs and long-term, trouble-free operation.Q: What are the main benefits of using an electric motor-driven screw conveyor?

A: Electric motor-driven screw conveyors offer reliable, adjustable rotation speeds for optimized material handling. They provide consistent performance, energy efficiency, and compatibility with automated feeding systems, making them suitable for high-capacity and continuous operation environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese